SS-PREP® 18Ni300 Prealloy Spherical Powder

18Ni300 maraging steel (also called MS1, 1.2709) is widely used in the industrial field. It was first developed by INCO in the 1960s. The yield strength is around 1030~2420Mpa, and the highest could reach 3450Mpa.

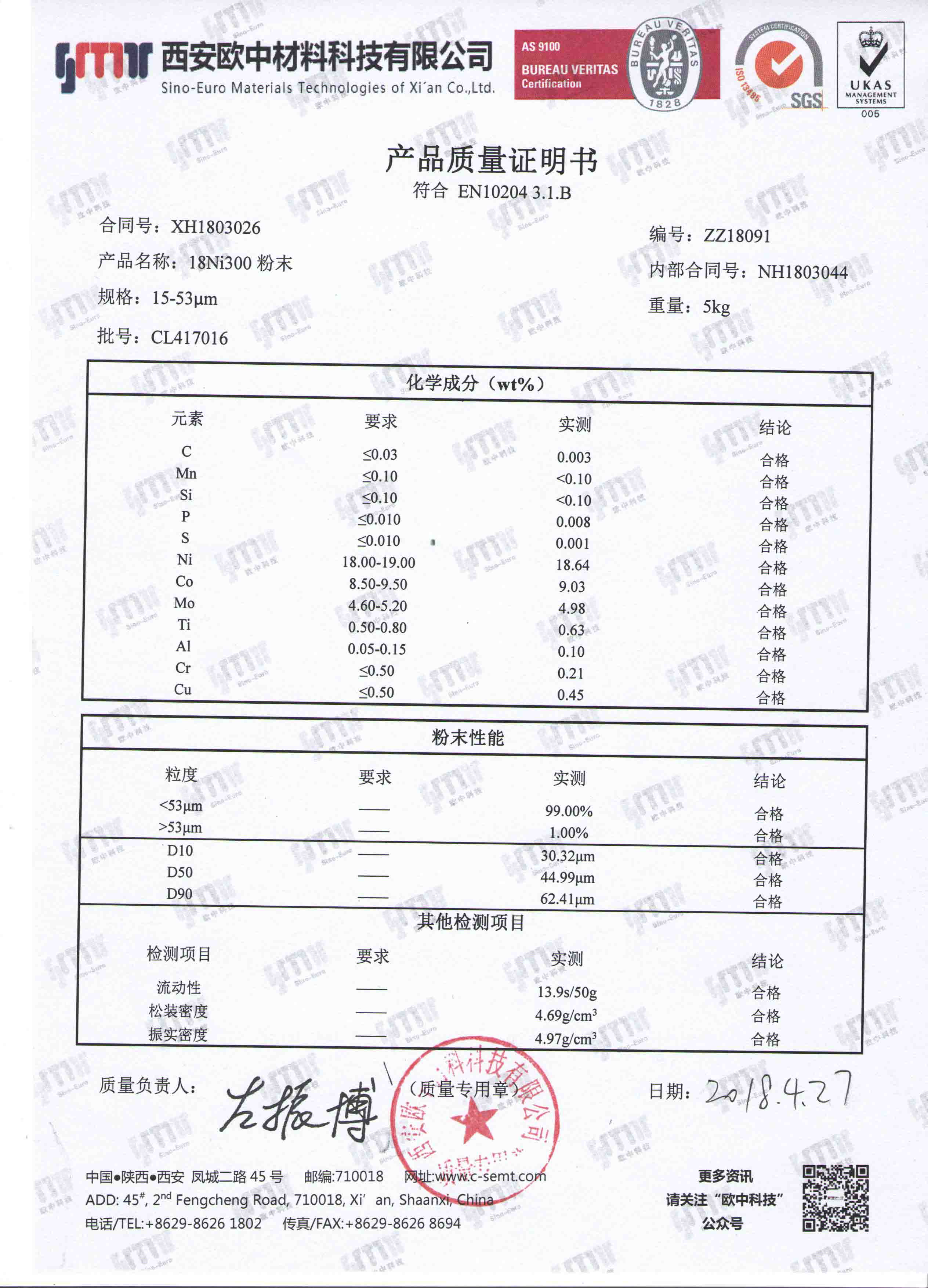

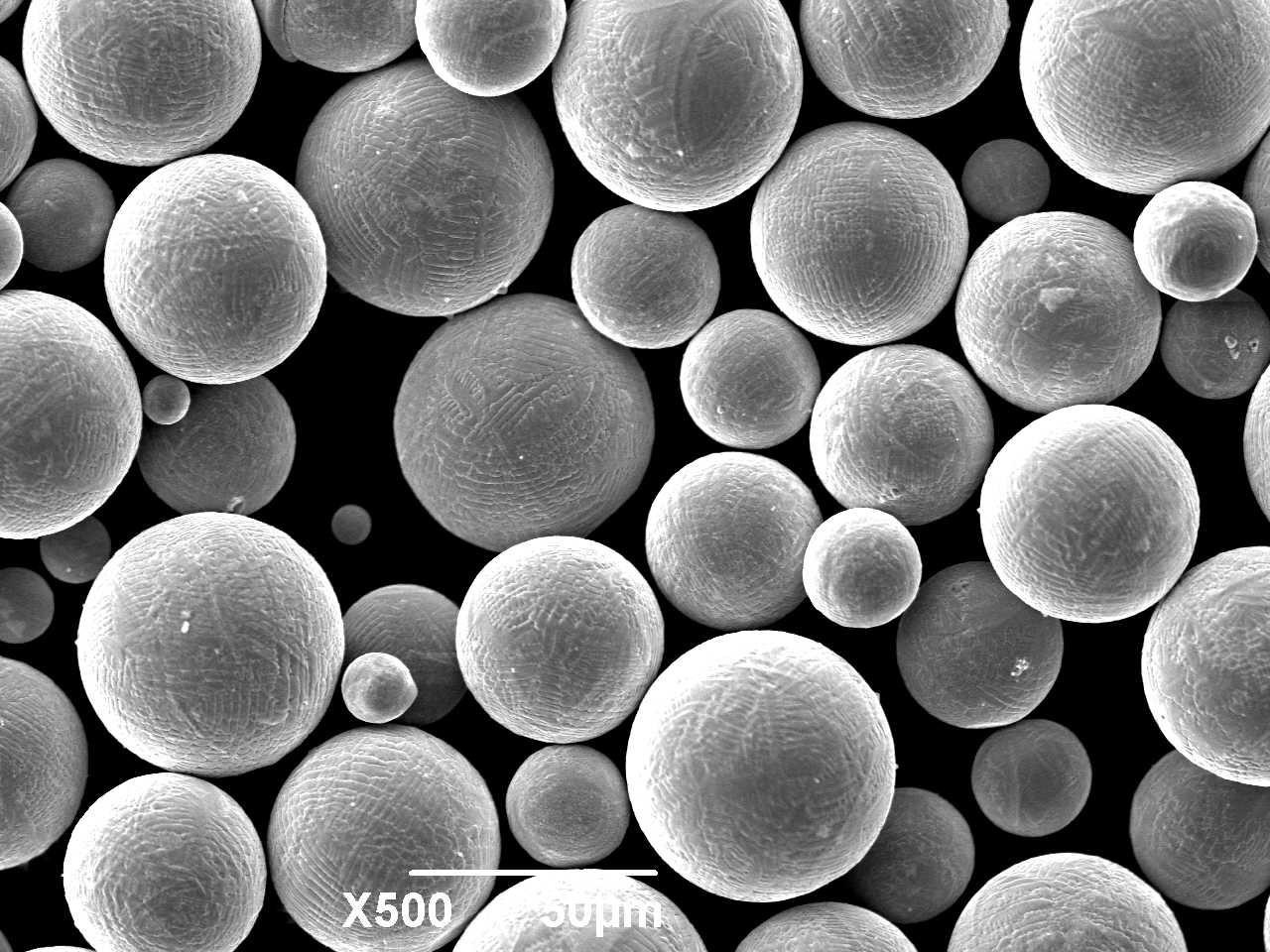

Sino-Euro has recently developed SS-PREP® 18Ni300 prealloy spherical powder. Fig. 1 displays the properties and chemistry of 18Ni300 powder. Hall flow speed with 2.5mm calibrated orifice is 13.9s/50g. Tap density is 4.97g/cm3. Apparent density is 4.69 g/cm3. Fig. 2 show the powder morphology.

Figure 1 The COA of SS-PREP® 18Ni300 prealloy spherical powder launched by Sino-Euro.

Figure 2 SEM morphology of SS-PREP® 18Ni300 prealloy spherical powder

Supreme-Speed Plasma Rotating Electrode Process (SS-PREP®) is the method for producing metal powders where the end of a metal bar is melted while it is rotated about its longitudinal axis. Molten metal is centrifugally ejected and forms droplets that solidify to spherical powder particles. The electrode is melted by non-transfer plasma with over 30000 Revolutions Per Minute (RPM) rotating speed. Causing about 20-50microns thickness of melting area, powders possess better chemical uniformity for every particle. There is no big chemical gap among different particles.

Sino-Euro Materials Technologies of Xi’an Co., Ltd.(Sino-Euro) is a subsidiary company of NIN Group(www.c-nin.com). The capital investment is about 15 million US dollars. Sino-Euro is specialized in powder metallurgy, Prealloy Spherical SS-PREP® Powder, Additive Manufacturing Wire, Bar & Substrate, and HIP service & components. Sino-Euro has been authorized with AS9100D, ISO9001 and ISO13485 Quality Management System.

Navigation

Follow Us